Kiswel

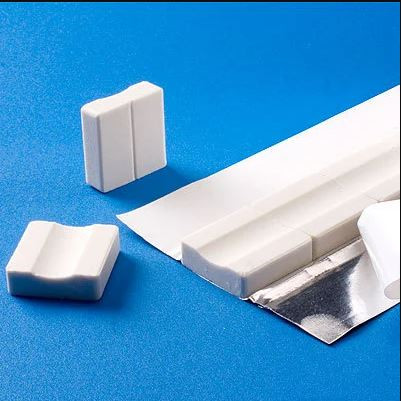

KST-316L Line-Up

Welding of low carbon molybdenum bearing austenitic alloys. Welding of 18%Cr-12%Ni-2%Mo steel where the corrosion resistant qualities are required